- Home

- Moving Bed Bioreactor (MBBR)

Moving Bed Bioreactor (MBBR)

H20 MBBR Process For Industrial And Domestic Wastewater Treatment

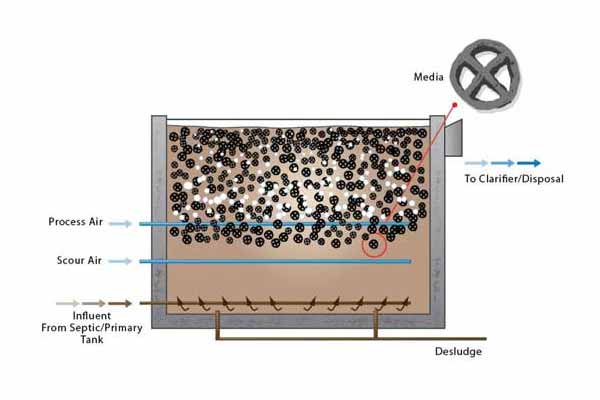

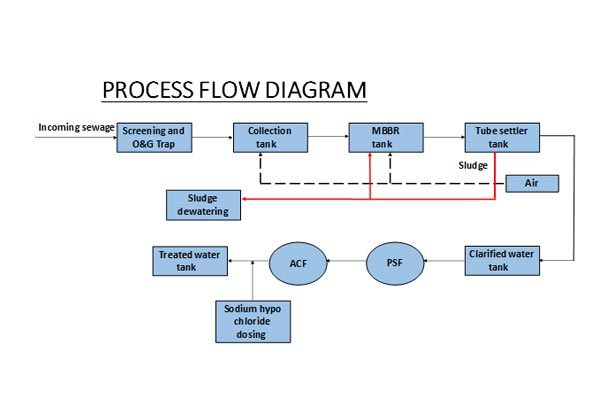

MBBR or Moving Bed Bioreactor reactor is a high rate attached growth aerobic treatment system wherein the bacterial growth takes place on a media submerged in wastewater. MBBR process uses the floating type plastic media for the attached growth process. Treatment units based on MBBR are operating successfully worldwide, as the technology is proven and simple to operate. The major advantages include a compact, efficient design (less than a half of conventional plants), low sludge generation, low odour and low visual impact, and simple maintenance requirements.

The assurance from H2O is that the treated wastewater will be entirely capable of being used for many reuse applications, as it will be clear, free from colour, and free from odour. The life cycle maintenance cost of the system will also be substantially lower than conventional systems.

Advantage Of MBBR Process

- Less space requirement: Higher loading of BOD on the media enables to reduce the aeration tank size. MBBR requires 60 % lesser tank volume as compared to activated sludge process.

- High surface aera attached growth process: Based on attached growth process, where media is floating in aeration tank, hence it provides maximum surface area.

- Less sludge generation: Rate of sludge generation is normally lesser as compared to conventional system.

- Long life span: Life of MBBR system is long due to use of as inert PVC media material is used. Non pressurized system.

- High degree treated water: All these process produces better quality treated wastewater than conventional activated sludge process.

- Low maintenance: No fixed structure in aeration enables for easy maintenance operation.

- Less power consumption : Due to use of diffused aeration power consumption is less. Small reactor size also helps to reduce power requirement, maintenance problems.

Applications :

- Domestic wastewater in residential and commercial buildings

- Condominiums & housing projects.

- Hospitals, Hotels & resorts, Shopping Malls

- Small and medium size factories, manufacturing units,

- Schools & Institutes

- Building temporary facilities.

- Petrochemical and field operations

- Site offices, labour colonies, construction sites.

- Golf Courses

- Dairy processing (milk, cheese, yogurt)

- Beverage factories (breweries, juice, soda)

- Automotive Industry

- Metal plating and finishing

- Municipal sewage plants

- Pulp & paper

- Aquaculture & hatcheries

Specifications & Special Features:

- Use of high-grade virgin PP bio film media

- Optimum design for MBBR process

- Available in many configuration and options for various types of MBBR biofilm media

- Adequately designed pre and post treatment

- Easily expandable and suitable for augmentation projects of old treatment plants.

- Suitable technology for phase wise operation & startup of system.

Moving Bed Bioreactor, H20 MBBR Process For Industrial And Domestic Wastewater Treatment In Mumbai, India