- Home

- Membrane Bioreactor (MBR)

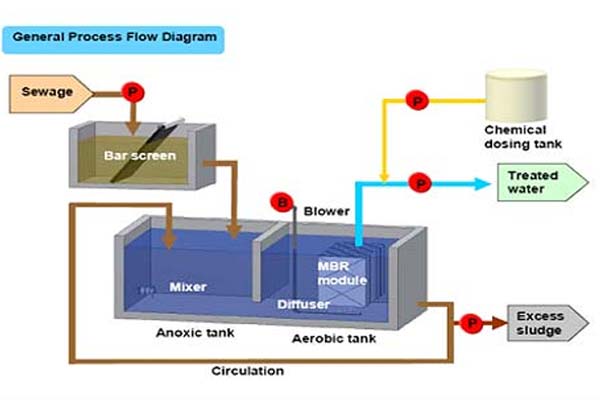

H2O MBR PROCESS

H20 MBR Process For Industrial And Domestic Wastewater Treatment

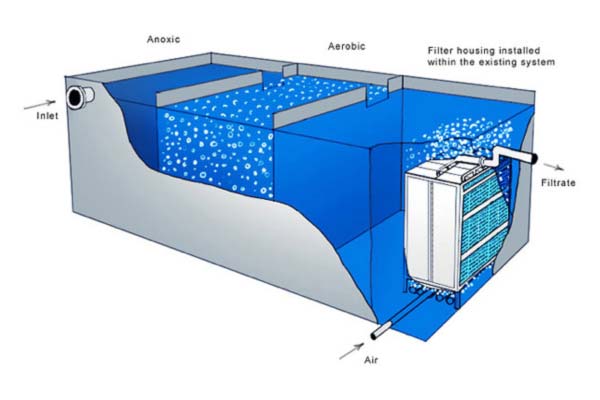

Membrane bioreactor (MBR) technology is well positioned to play a critical role in reuse applications. Technological advances of the process over other wastewater treatment process is as efficient and effective. From retrofits to decentralized plants, MBRs are a versatile treatment platform that can help change perception and turn wastewater into a viable resource. When looking into advanced water reuse applications, MBRs represent the best product quality for reuse application in smallest footprint.

MBR systems allow the complete physical retention of bacterial flocs and virtually all suspended solids within the bioreactor.

As a result, the MBR has many advantages over conventional wastewater treatment processes. These include small footprint and reactor requirements, high effluent quality, good disinfection and odor control capability, higher volumetric loading and less sludge production. As a result, the MBR process has now become an attractive option for the treatment and reuse of industrial, domestic and municipal wastewaters.

Advantage Of MBR Process

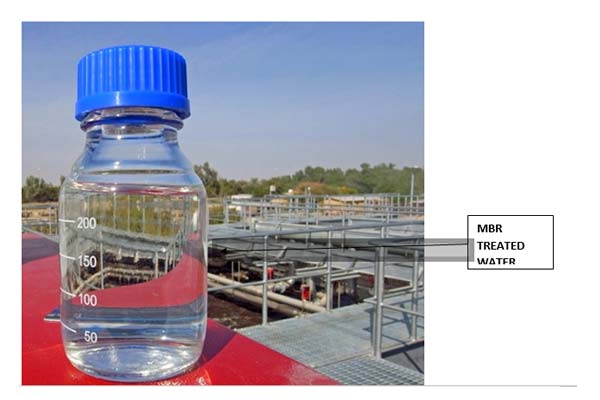

- Highest degree treated water

- In terms of low turbidity, TSS, BOD, and bacteria

- More robust process

- Ability to absorb shock loads

- Reusable quality treated water, saves freshwater requirement

- Treated water can be directly reused for many applications

- Efficient in Biological Nutrient Removal

- Eliminates environmental hazard of surrounding due algae growth

- Smaller Footprint

- Low hydraulic retention time and hence low foot (area) requirement

- Low Maintenance

- Automated operation, minimum chances of human error

- Retrofit/Upgrade

- Due to high MLSS system can be upgraded to high capacity.

- Reduced Disinfection Requirements

- Membrane barrier separates bacteria and virus up to log 4

Customer Benefit With H2O MBR Process:

- One stop solution

- H20 Provides complete MBR process solution along with pre and post treatment.

- Concept to commissioning

- Complete design solution and process backup with experienced inhouse engineering team.

- Multiple options

- Represents multiple membranes brands and providing selection meeting to customer requirements.

- Automation and integration support

- MBR process works on Automation H2O offers complete automation solution for your MBR system

- Overall responsibility, service and backup support & aftersales services.

Applications :

- Domestic wastewater in residential and commercial buildings

- Condominiums & housing projects.

- Hospitals, Hotels & resorts, Shopping Malls

- Small and medium size factories, manufacturing units,

- Schools & Institutes

- Building temporary facilities.

- Petrochemical and field operations

- Site offices, labour colonies, construction sites.

- Golf Courses

- Dairy processing (milk, cheese, yogurt)

- Beverage factories (breweries, juice, soda)

- Automotive Industry

- Metal plating and finishing

- Municipal sewage plants

- Pulp & paper

- Aquaculture & hatcheries

Specifications & Special Features:

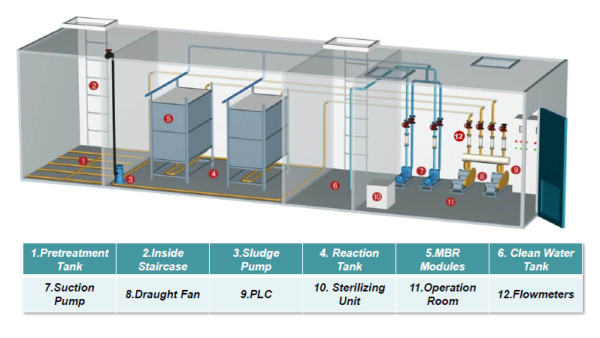

- Available in any capacity, in prefabricate package compact type & in civil tank type configuration.

- Use of best matched and most sturdy membrane, low fouling, long life membranes as per nature of effluent.

- Optimum design for MBR process with low power requirement and lower op.ex.

- Available in many configuration and options in type, Material of construction,

- Adequately designed pre and post treatment

- Easily expandable and suitable for augmentation projects of old treatment plants to enhance capacity and quality of treated water.

- Suitable technology for phase wise operation & start-up of system.

H2O MBR Standard Model Configuration :

| Model Code | Capacity | Type | Features |

|---|---|---|---|

| A. Containerized MBR System | |||

| HPCMBR10 to 50 | 1KLD- 50 KLD | Prefabricated Transportable MBR system in MS / CS / SS tanks. Anticorrosive painting or lining option available. | Suitable option for export application can be fitted in standard 20ft High cube ISO container |

| HPCMBR100 | Further up to 100 KLD | Suitable option for export application can be fitted in standard 40 ft High cube ISO container | |

| HPCMBR250 | 100 KLD to 250 KLD | Suitable option for export application can be fitted in standard 40 ft High cube ISO container with multiple tanks | |

| B. Prefabricated MBR system | |||

| HPFMBR 5-500- MS | Up to 500 KLD | Packaged Prefabricated non containerized transportable MBR system With Mild steel epoxy painted tank Anticorrosive painting or lining option available. | Prefabricated single or multiple tank system suitable for domestic application |

| HPFMBR 5-500- CS | Up to 500 KLD | Packaged Prefabricated non containerized transportable MBR system With CS epoxy painted tank Anticorrosive painting or lining option available. | Prefabricated single or multiple tank system suitable for domestic application |

| HPFMBR 5-500- FRP | Up to 500 KLD | Packaged Prefabricated non containerized transportable MBR system With FRP tanks | Prefabricated single or multiple tank system suitable for domestic application |

| C. Customized MBR system | |||

| HCMBR | 5 kld and onwards | Custom design MBR system with civil construction tanks. | Tanks with Civil construction suitable for any capacity |

Membrane Bioreactor, H2O MBR Process, H20 MBR Process For Industrial And Domestic Wastewater Treatment In Mumbai, India