- Home

- H2O Package Wastewater Treatment Plants

H2O Package Wastewater Treatment Plants

A Preconstructed Unit Customized To Your Needs

H2O designed packages preconstructed wastewater treatment units uses integration of various treatment process to achieve clean, pollutant free treated water which can be reused for many secondary uses and with significantly lower maintenance. The treatment process is based on worldwide proven technologies however customized to create hassle free operation for users which are in form of plug and play mode. It minimizes operation issues, space requirement, construction cost and time and completely transportable worldwide. Package wastewater treatment units provides better aesthetic view of treatment units which will not fade beauty of customers premises. Treated product water quality can be optimized to highest degree as per reuse application and meeting as per local government norms. The system is fully capable of removing organic & inorganic substance, colloidal particles, suspended solids, pathogens etc.

Packaged units come in standard modules with capacities ranging from 5 m3/day to 200 m3/day. Further any capacity can be provided by providing multiple treatment tanks.

Special Features:

- Compact & robust design with long life,

- Easily transportable worldwide

- “all-in-one” single tank unit.

- Any Capacity, Any Effluent Requirements.

- high quality treated water

- minimal land usage (smaller foot print)

- Use of reputed components

Advantages:

- Easy start-up & rapid installation

- Design based on specific application.

- Modern control system with MCC or PLC based operating system.

- Low maintenance.

- Low power consumption.

- Easy operation no high skilled labour required.

- Low & odourless operation

- Can be installed in basement area with less height

- Less civil work involved.

Applications :

- Domestic wastewater in residential and commercial buildings

- Condominiums & housing projects.

- Hospitals, Hotels & resorts, Shopping Malls

- Small and medium size factories, manufacturing units,

- Building temporary facilities.

- Schools & Institutes

- Petrochemical and field operations.

- Site offices, labour colonies, construction sites.

- Golf Courses

Specifications:

A. Material Of Construction:

- Package Treatment unit with available options for material of constructions as follows:

- Mild steel with epoxy painting (MSEP)

- Mild steel with FRP lining

- CS (carbon steel) with epoxy painting

- FRP (Fiberglass reinforced plastic)

- PP FRP

B. Capacity:

- Standard single tank design units available for:

- 5KLD to 125KLD for domestic STP

- 5KLD to 75 KLD for export and skid mounted STP units.

- 5KLD to 100 KLD for domestic industrial application containing biodegradable organic effluent (COD< 2000mg/l)

- 5KLD to 50 KLD for export industrial application containing biodegradable organic effluent (COD< 2000mg/l)

- Further customized multi tank design for other applications.

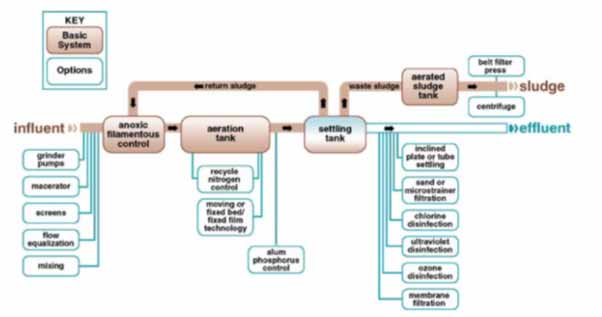

Treatment Technology

Primary Treatment

- Standard single tank design units available for:

- Neutralization, equalization, Oil removal, screening etc.

- Control Unit & Instruments

- MCC / PLC panel (Optional), Standard panel

- Level controllers for pump dry run protection

- Pressure gauge, Rotameters, Flow meters as per requirement

- 440 V, 50 HZ, 3 pH power connection

- Biological Treatment Options

- Extended aeration.

- MBBR (Moving Bed Biofilm Reactor)

- SBR (Sequential Batch Reactor)

- MBR (Membrane Bio Reactor)

- Integration of treatment units for industrial effluent treatment

- Tertiary treatment Options

- Filtration with sand/ activated carbon

- Bag filtration/ disc filtration

- Disinfection with Sodium hypo Chlorite, Chlorine dioxide

- Disinfection with Ozone

- Disinfection with UV, H2O2

- Advance filtration using Ultrafiltration

- Service / Sales support

- Dedicated service and after sales support team

- Operation & maintenance manual

- Installation and commissioning service.

- Fabrication Features

- Fabrication with good engineering practice

- Skid mounted unit

- Enclosed units and equipment’s in containerized systems

- MILD steel/Carbon Steel tanks with red oxide primer and anticorrosive paint.

- High grade FRP lining.

- Branded components/ Equipment’s/ Pipes/ Electrical fixtures

Comparison Of Packaged STP Vs. Conventional Sewage Treatment Plant

| Parameter | Packaged STP | Conventional STP |

|---|---|---|

| Space requirement | Reduced due to less thickness of partition walls | Large area required due to civil construction walls. |

| Process Tanks | Process Tanks Pre-Fabricated tanks. | Civil tank (to be built by client) |

| Portability | Easy for relocating to other places. | Fixed construction in civil cannot be moved. |

| Treated Water Quality | Treated Water Quality High Quality, can be used directly for Gardening, Cleaning, process. | May require further treatment. |

| Operation & Maintenance | Easy for operation and maintenance. Virtually no manpower required. | Tedious for maintenance of MLSS and achieving the end quality |

H2O Package Wastewater Treatment Plants In Mumbai, India